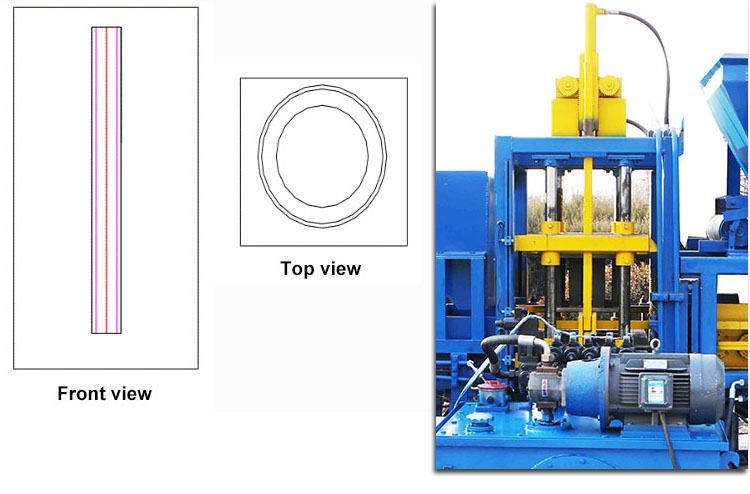

Guide rod, the very important component of block brick machine

The guide rod is used in the mold and components to ensure that the mold moves with accurate positioning to guide the mold stroke. Therefore, the guide rod is one of the most important components of the brick making machine. The performance and technical requirements of the guide rod have great influence on the brick machine. Bearing steel, hot working die steel and easy turning iron are generally selected as the material of guide rod and guide rod assembly. However, bearing steel SUJ2 is widely used, which greatly enhances the durability and interchangeability of guide rod in guiding performance. The guide rod and components constitute the outer and inner guide rod components, which have beautiful metallic luster.

Heat treatment of guide rod: HRC58-62. The surface roughness of opposite direction rod: Ra0.8, ral.6.

The number of oil grooves increases with the length of the guide pillar, and the number of oil tips with the limit of M is generally 8.

Calculation of length of inclined guide pillar:

The length of section C of inclined rod is very important, and its length controls the running distance s of sliding block. In fact, the calculation of the length of the inclined guide pillar is based on the "trigonometric function". We can simplify it into a triangle, which is convenient to use the trigonometric function formula. Set s is the sliding distance s of the slider in the pavilion, and the angle X is the angle D in the pavilion. (these two numbers have been set as fixed values according to the needs of product and mold design, which are known numbers.) The length L is relative to C in the pavilion. The height h is the opening distance of the mold when the slider slides to the finger positioning device. In this way, the calculated value is only in the ideal state.

Determination of the angle of the inclined guide pillar in the mold:

The angle of the slanting rod of the mold is usually 20 degrees or 25 degrees. Generally, the angle of 20 degrees is used. If the sliding block moves a little longer, the 25 degree angle can be used. If the distance is longer, hydraulic or pneumatic methods should be used.

The function of the center hole of the guide rod is as follows:

The roundness of the guide rod has high requirements. The main purpose of drilling the center hole is to use an external grinder to grind the outer diameter. When grinding the outer diameter with the cylindrical grinder, the center hole must be supported by the center hole to make the guide pillar rotate before grinding.

If you have a better understanding of the guide rod, you will be able to use the brick block machine better. Because whether it is a concrete block machine or a clay brick machine, the guide rod is an essential and important component.