High-end technologies adopted by FULANG brick block making machinery

This month, three sets of m7mi FULANG interlocking brick making machinery were produced and ready to be sent to the United States, and three sets of m7mi were also completed and ready to be sent to Cameroon. A QTF4-25B automatic concrete block making machine is also ready to be sent to Botswana. One QTF4-28 has been produced and ready to be sent to Nigeria. A QTF4-25A has also been produced and ready to be sent to Haiti. One FL2-10 has been produced and ready to be sent to India. One QTF4-18 has been produced and ready to be sent to Uganda.

Why is FULANG machinery so popular with foreign customers?

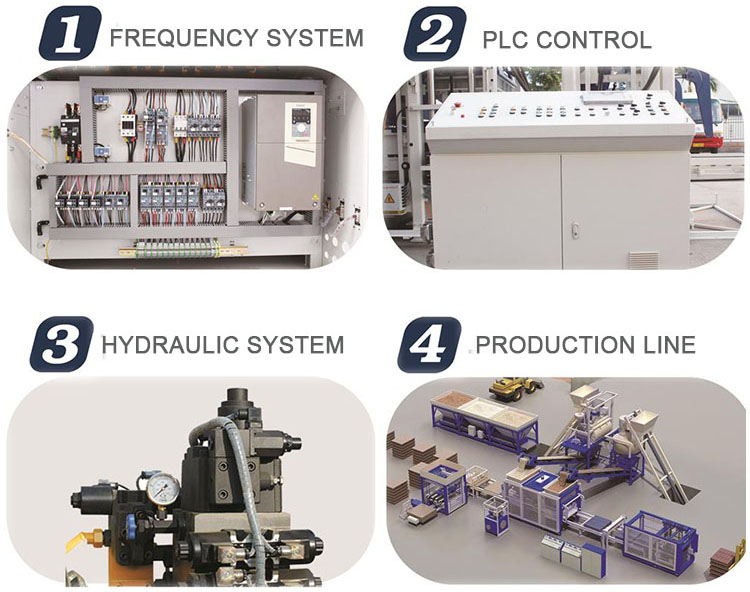

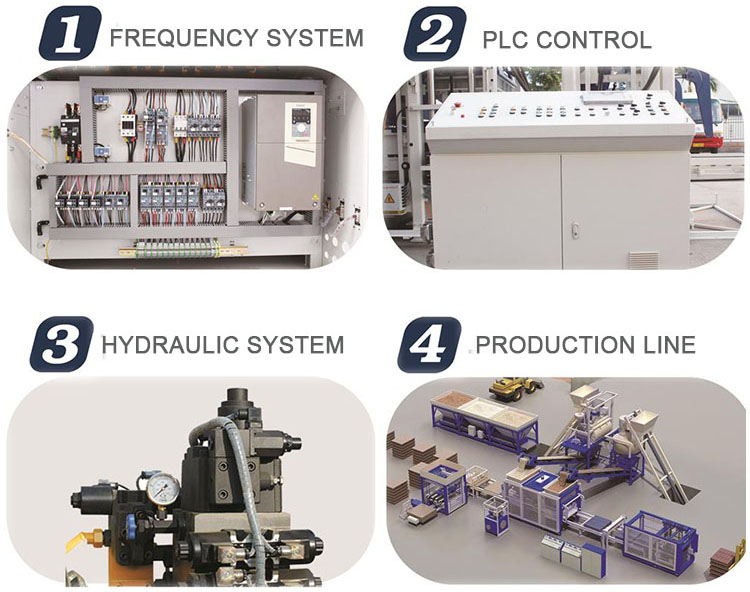

Let's take stock of the high-end technologies adopted by FULANG machinery, so that foreign customers like their products so much.

1. The introduction of German advanced block machine technology and German advanced frequency conversion technology perfectly combine the four aspects of high production efficiency, energy saving and environmental protection, higher product density and multi-function. Through the advanced PLC centralized control technology, fast and efficient man-machine dialogue can be realized.

2. The machine body adopts thick wall square tube, which is thick and steady to ensure the body is firm and shock resistant. At the same time, the height of the shaking table is reduced, so that the center of gravity of the fuselage is extremely low, and 95% of the aftershocks can be introduced to the ground, which effectively reduces the damage of the vibration to the fuselage, thus greatly prolonging the service life of the equipment.

3. Advanced precise control technology is adopted to precisely control the movement of the ram. Adjustable synchronous swing arm is installed on the ram and demoulding frame to ensure that the error of indenter and demoulding is within 1 mm.

4. Concrete block making machine adopts advanced vibration pressure separation technology, install auxiliary pressure head and vibration support plate, and equip with shock absorption rubber pad to completely block the interference of vibration on the pressure of pressure head. To achieve real vibration pressure separation. This is the top technology in the brick machine industry.

5. All brick making machines adopt advanced extended high efficiency vibration technology. The molding time is shorter and the compactness is higher. At the same time, the vibration spindle adopts universal joint drive shaft to ensure accurate transmission speed, reduce energy consumption and unnecessary friction. The service life of the drive belt is greatly prolonged.

6. The abrasives are refined by high temperature carburizing heat treatment technology and advanced wire cutting technology, which is more wear-resistant and stronger.

7. All block machines adopt Imported pure components of high-efficiency hydraulic proportional system, intelligent PLC touch screen and pure electrical components. Higher degree of automation, easier operation, and its excellent quality ensures its longer service life.