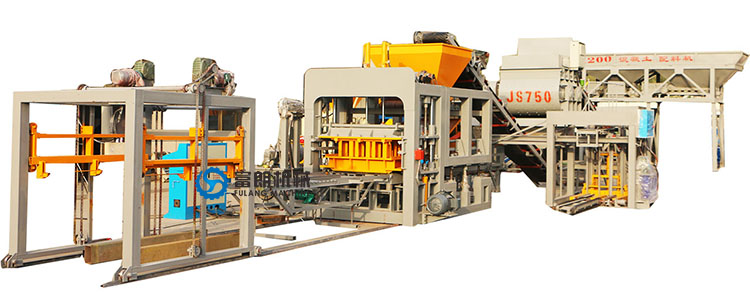

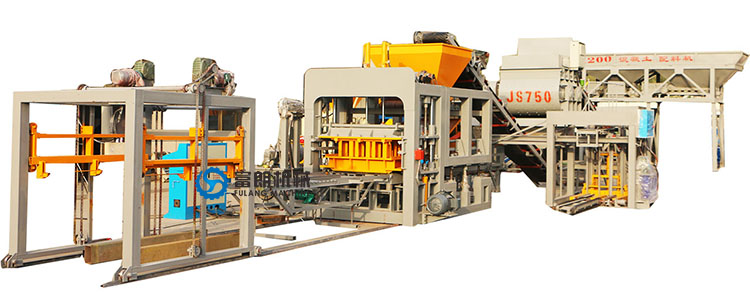

How to better maintain the hydraulic system of brick making machine equipment?

Hydraulic system is one of the core components of hydraulic brick making machine. Hydraulic system uses oil as medium to convert and transfer energy. In the energy conversion engineering, due to the low efficiency of energy conversion, the power loss of hydraulic system almost turns into heat, resulting in the temperature rise of hydraulic oil. Especially in the case of high working environment temperature, the oil temperature of the hydraulic system often exceeds 60 ℃, so it is often forced to shut down and start production after the oil temperature drops. This not only seriously affects the production, but also reduces the viscosity and wear of the hydraulic system due to high oil temperature, which leads to the decline of hydraulic system performance, slow down of action and reduction of molding pressure The aging and deformation of the rubber seal results in the leakage of hydraulic oil, resulting in shutdown and maintenance. In order to better maintain the hydraulic system, it is also necessary to strictly implement the operating procedures in daily use.

Daily management of hydraulic system

1. Strictly implement the operation procedures

For equipment managers and operators, they should be familiar with each key link of the operation procedures and strictly abide by them, with special emphasis on the following points:

(1) Check before starting the pump. Before starting the pump, the oil temperature and oil level of the oil tank must be checked. If the oil needs to be replenished, the oil of the same brand must be used, and the special oiler should be used to fill the oil tank. If the oil temperature is lower than 15 ℃, the system should be operated under load for more than 20 minutes. Check whether the hydraulic components and external actuators are in reset state.

(2) Pump start-up and inspection after start-up. It is very important for block making machine. When the pump is started, it will run for 5 minutes without load. Observe whether the pressure, noise and vibration indication signals of the system are normal. If any abnormal phenomenon is found, stop the operation of the pump immediately, and restart the oil pump after finding out the cause and solving the problem.

(3) Inspection during system operation. Under the stable operation of the hydraulic system, in addition to paying attention to the oil temperature, oil volume, noise and pressure at any time, it is also necessary to check the working conditions of the pressure parts of the vehicle, pay attention to the oil leakage, pressure, vibration, throttle speed of the whole system, and timely eliminate the faults when problems are found.

2. Requirements for users

To a great extent for brick machine, the hydraulic system has realized the integration of mechanical, electrical and hydraulic, and has a high degree of automation. Its maintenance and management have higher requirements than other building materials and equipment. What's more important is the requirements for management personnel: they should have rich knowledge of machinery, electrical appliances and control, and equipment maintenance personnel should have certain knowledge of fitter, electrician and hydraulic pressure.